Introduction to AC Coils

While purchasing a Blue Star air conditioner, most of us look at nothing but the ‘stars,’ tonnage, and ‘price.’ However, there’s one seriously vital part of an AC that is commonly neglected—the AC coil. And let me tell you, my friends, it’s that one point that makes all the difference. So, the question is: Blue Star AC Copper Coil vs Aluminium Coil – Which Is Better?

What is an AC coil and why is it important?

Try to imagine that the AC coil is the “heart” of the air conditioner. It is responsible for absorbing the heat from the room and then releasing it outside. The quicker and more effectively it does that, the better the cooling effect. If it’s a struggle for the coil, it’s a struggle for your AC. Period.

Comprehending the Copper Coil of the Blue Star Air Conditioner

What Is a Copper Coil

A copper coil is made up of, you guessed it, pure copper tubing. Blue Star employs quality copper in their top-end ACs. Copper has long been the accepted standard, and there is a reason for this.

How Copper Coils Function

Copper conducts heat more quickly and more effectively. This entails that:

- Faster cooling

- Stable temperatures

- Reduction in the Workload of the Compressor

It is like having a fast highway for heat transfer instead of a narrow street.

Copper Coil Manufacturing Quality

Blue Star uses anti-corruption coating and carefully welded copper coils to increase reliability and efficiency, particularly in more humid and near-coastal areas.

Introduction to Aluminum Coil in Blue Star AC

What is an Aluminium Coil

In an aluminum coil, the making is done with aluminum tubing instead of copper. This type of coil can also be seen in low-budget and medium-range ACs.

How Aluminum Coils Work

Aluminum can conduct heat, but it does so nowhere near as well as copper. In order to compensate for this, manufacturers commonly use thicker coils in an effort to achieve similar results, which makes it a bit larger in size and less responsive.

Aluminium Coil Construction

Most of the coils in aluminium are joint-less; this reduces the risk of leakage, but on the other hand, repairs are more complicated in case of damage.

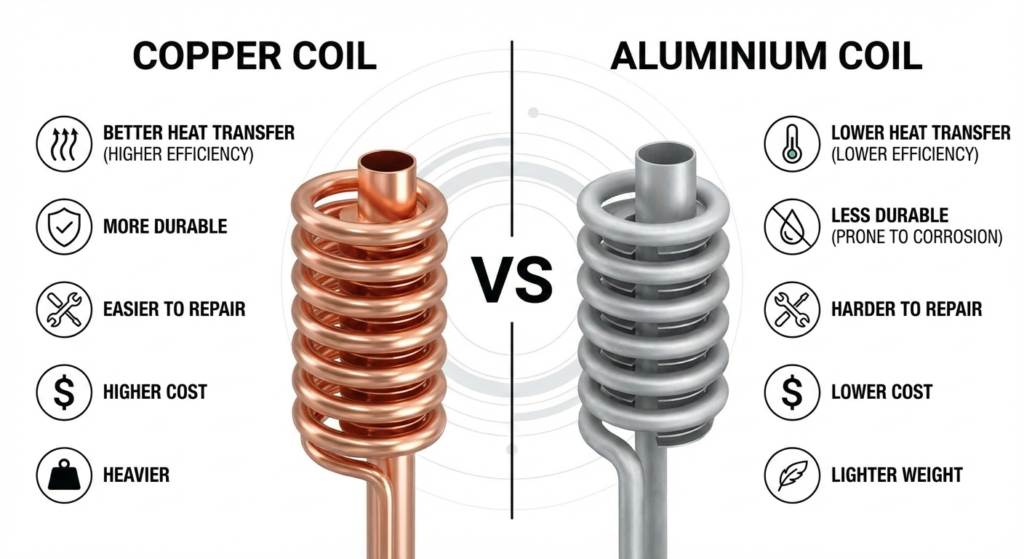

Copper Coil vs Aluminium Coil: Main Differences

Cooling Efficiency Comparison

- Copper Coil: Rapid conduction of heat, fast cooling

- Aluminium Coil: Slightly slower cooling rate

If quick cooling is what you are looking for, copper is the winner—hands down.

Durability and Lifespan

- A copper connection is more robust and has a flexibility advantage over fibre optics, which are less susceptible to cracking and wear.

- Aluminium is more fragile than copper but has a weight advantage over fibre optics.

Proper installation also impacts the lifespan of AC coils. Incorrect installation may lead to leakage or reduced efficiency. Follow the correct installation process by referring to our step-by-step Blue Star AC installation guide

Maintenance and Repairs

- Copper coils are more easily repaired and less expensive to fix compared to wood or iron

- Aluminium coils may need a complete replacement

Copper is considered fixable while aluminium is replaceable.

Corrosion

Copper has better natural resistance to corrosion. Aluminium requires additional protective coats, particularly in wet or coastal regions.

Copper Coil vs Aluminium Coil in Blue Star AC

| Feature | Copper Coil | Aluminium Coil |

|---|---|---|

| Cooling Speed | Faster | Moderate |

| Heat Transfer | Excellent | Average |

| Durability | High | Medium |

| Repair Cost | Low | High |

| Corrosion Resistance | Better | Lower |

| Lifespan | 8–12 years | 5–8 years |

| Initial Cost | Higher | Lower |

| Long-Term Cost | Lower | Higher |

Overall Winner: Copper Coil

Energy Efficiency and Power Consumption

The coils are made of copper, which enhances the flow of heat. This means the compressor will work less.

- Reduces power consumption

- Improved energy efficiency

- More stable performance

The effect: as follows, this will be reflected in your electricity bill over time.

Cost Comparison: Copper and Aluminum

- Copper Coil AC: Cost is relatively high

- Aluminium Coil AC Less expensive upfront Aluminum

But there is a twist—the copper ACs tend to be more economical over time because of increased efficiency and low maintenance costs.

Maintenance Cost Comparison: Copper vs Aluminium Coil

| Maintenance Aspect | Copper Coil | Aluminium Coil |

|---|---|---|

| Repair Possibility | Easy | Difficult |

| Welding | Possible | Not recommended |

| Replacement Cost | Moderate | High |

| Service Frequency | Low | Higher |

Over 5–7 years, copper coil ACs usually cost less to maintain despite higher purchase price.

Performance in Indian Climate Conditions

Indian weather is not something to be taken lightly—high temperatures, humidity, dust, and voltage variations.

Copper coils work much better in such situations. This is why Blue Star prefers copper coils in:

- Coastal zones

- High-humidity regions

- Heavy summer usage

Indian weather conditions such as high humidity, coastal air, and extreme summers can impact AC performance. Copper coils are more suitable for such environments. If you live near the sea or in a humid region, don’t miss our guide on the best Blue Star ACs for coastal areas in India

Which Coil Is More Suitable for Long-Term Use

If you are planning to use the AC in 5 to 10 years, it is always better to choose copper. It is good, consistent, and also suitable in case you have to repair it.

“Aluminum” is all right:

- Budget is tight

- The usage is limited

- You intended the product’s short-term use

Does Blue Star Use Copper Coil or Aluminium Coil?

Blue Star primarily uses 100% copper coils in most of its split AC and inverter AC models. Aluminium coils are generally limited to:

- Entry-level models

- Budget-focused window ACs

- Selected older designs

Blue Star openly promotes copper coil technology because it aligns with Indian climate conditions and long-term durability requirements.

Which Coil Is Better Based on AC Tonnage?

1 Ton Blue Star AC

- Copper coil recommended for faster cooling

- Aluminium acceptable only for light usage

1.5 Ton Blue Star AC

- Copper coil strongly recommended

- Handles higher heat load efficiently

2 Ton Blue Star AC

- Copper coil is a must

- Aluminium coils struggle under heavy load

For higher tonnage ACs, copper coils significantly improve performance and lifespan.

Copper Coil vs Aluminium Coil in Inverter ACs

In inverter ACs, the compressor runs continuously at variable speeds. This makes coil efficiency even more important.

Why Copper Coil Is Better for Inverter ACs:

- Better heat dissipation

- Stable compressor operation

- Lower stress on inverter PCB

- Improved energy efficiency

Best Combination:

Blue Star Inverter AC + Copper Coil

Conclusion

Hence, Blue Star AC copper coil vs aluminium coil – which is better?

If you want:

- Quick Cooling

- Increased durability

- Lower Maintenance

Opt for a Blue Star AC with a copper coil.

Aluminium coils may be cheaper, but copper coils give you a payback, much like investing in something intelligent.

FAQs

1: Is a copper coil AC really worth the added cost?

Yes. Over the years, greater efficiency and reduced costs for repair make copper coil A/Cs more economical.

2: Will Blue Star aluminium coil ACs cool well?

They cool well but not as quickly and regularly as copper coil models.

3: Which coil has a longer lifespan—copper or aluminium?

Copper coils have longer lifetimes because of their strength and ability to resist rust.

4: Are copper coils easier to repair?

Of course. Copper coils are easy to weld and repair, unlike aluminium coils.

5: Which coil is best suited for beach locations?

Copper coils are highly advisable in areas that are close to the beach or are very humid.